-

About

- About Listly

- Community & Support

- Howto

- Chrome Extension

- Bookmarklet

- WordPress Plugin

- Listly Premium

- Privacy

- Terms

- DMCA Copyright

- © 2010-2025 Boomy Labs

Jaydeep Chauhan

Jaydeep Chauhan

Listly by Jaydeep Chauhan

There’s a growing trend for mass customization as customers look for personalized products while manufacturers seek a competitive edge in the market. Customization help companies to differentiate their products from those of competitors, especially in today’s stiffened market competition, where customers make use of internet to compare prices and features to choose a particular product.

Shop drawings are contractor’s drawn version of information shown in the construction documents 2D CAD drawings using SolidWorks & they showcase more details than the construction documents. They are drawn to explain the fabrication and/or installation of the items shown through Mechanical drafting and 3D models in the process of Product design and development.

Retail shopfitters have actively played a crucial role in building a successful business in today’s concurrent market dynamics. Not to forget that the customers are attracted by the design of the shop or your retail store. If your retail shopfitter, with assistance of 3D CAD designers, has helped you to set it up in the best way, then it will definitely attract more customers. The products in your store need to be displayed in a unique and creative manner.

Gaining efficiency in product design and manufacturing is what every manufacturer would want, in order to bring products to market faster and remain profitable. Thanks to the advancement in technologies in form of 3D CAD Designs & 2D CAD Drafting, which has brought a significant improvement in ways the products are being conceptualized, designed and manufactured today.

From materials to aesthetics, furniture has a different meaning for customers today, yet the focus remains the same – experience. The furniture design and manufacturing industry today is huge and the sales are expected to grow by 5% YoY in the United States alone.

Design automation is highly beneficial to such industries that develop products which although look the same, have the provision of customization for specific customer requirements.

Hi-Tech Engineering Services is efficient to deliver the high-quality & accuracy services such as sheet metal design, CAD design & drafting, 3D modeling & CAD customization for the fabricators.

Hi-Tech is a top-notch mechanical CAD drafting services from firm for the solid product manufacturer, fabricators, building product industrialist. Let’s get connect with us know more about our effective and high-accuracy services such as CAD drafting, CAD conversion, 2D & 3D drafting, fabrication and industrial products design.

2D and 3D CAD drafting is an essential factor for manufacturer & fabrication industries. Even mechanical drafting is not limited at all but it requires when the industries need to align for product design and development with highest-accuracy.

Rapid prototyping or more commonly known as the 3D printing technique has created a massive impact in the technology sector, redefining the way products are designed and manufactured. This potential technology is consistently being exploited to identify the feasibility of newer materials getting 3D printed.

Today, the growth of mechanical product design industry is rooted in the capabilities that CAD/CAE tools extend. Computer aided design and engineering not only enables the production of high performance, higher durability, improved sustainability and smaller footprint - mechanical product design concepts but also ensures that the product is manufactured with measurably less use of resources, man-hours and most importantly 'money'.

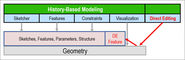

The intent of this article is to explain why we at Hi-Tech use SolidWorks, and the mechanical engineering design solutions including 3d modeling, virtual prototyping, mechanical drafting, product design & drafting services, sheet metal design and CAD design automation, that we delivered through 2500 + successful projects.

It has been more than two decades that 2D Drafting has played a vital role in the mechanical and engineering designs for manufacturing process. They have successfully provided significant and precise information on the tolerances and dimensions required for it and functionality of a part for product manufacturers. However; the bitter fact is that with advent of software and technological tools like SolidWorks, Inventor and many more alike, mechanical 2D CAD drafting is struggling to keep up in tune with the design and manufacturing industry, today.

Mechanical or industrial designers enjoy the best jobs in the world. Their jobs are fun, creativity and challenging. But not to forget that their CAD drawings and 3D CAD designs play an extremely important role in the product process, putting them under immense pressure at times.

From usual conceptualization of the display and fixture for a particular retail store to engineering and final manufacturing, it is often difficult to respond to the retailer’s requirement on time, especially when maintaining accuracy in the flexibility of the designs. Even a difference of 1% or 2% in price can cause the manufacturer loose the contract.

Successful business can be run not only by having a nice, elegant design, but these mechanical 3D CAD designs should also be environmental friendly, may it be with sheet metal or wooden. This is a small effort to portray the process of retail shop fitting and the key points that are involved in setting up an environmentally sustainable design.

2D CAD drawings have been with us since decades; they do this very important task of providing product manufacturing information to folks on the shop floor.

Shopfittings not only attract customers, but it works quickly in your favor to make more money. Professionally styled & designed to meet international standards, these display systems redefine your retail outlet or showroom display structures by revolutionizing shelving spaces.

Product manufacturers instead of being skeptical about RP, should embrace it with open arms. The more frequently they fail, the more innovative ideas they would come up with.

Furniture manufacturers today often find it difficult to maintain their businesses profitable due to fiercely competitive market. New entrants are coming up with engaging ways to lure customers and have obtained a significant profit share in the market.

In a world were manufacturing is digitizing and products are becoming smart through disruptive technologies like Internet of Things, there is an increase in the complexity and part count for these products. These changes are even more severely affecting industrial equipment manufacturers involved in pressure vessels or storage tanks, valves & fittings, where number of parts often reaches from hundreds to thousands.

Furniture manufacturers operating in retail industry are often faced with a challenge of developing and delivering customized furniture designed for retail stores of different architecture setting.

Companies globally, require multiple CAD systems to accomplish their product development objectives. The use of multiple CAD platforms could be at a departmental level within the organization or it could be required while communicating with outside vendors and customers.

The success of any new product relies mainly on the focus applied by the design and engineering team in the conceptual phase. Selecting the wrong concept directly impacts the design quality and increases the chances of failure. Moreover, it increases design complexity and unnecessarily elongates production time and cost due to design revisions.

Jaydeep Chauhan is an Engineering Analyst at Hi-Tech Engineering Services and takes care of design analysis and optimization of mechanical products & eq...