-

About

- About Listly

- Community & Support

- Howto

- Chrome Extension

- Bookmarklet

- WordPress Plugin

- Listly Premium

- Privacy

- Terms

- DMCA Copyright

- © 2010-2025 Boomy Labs

Listly by anthony-17

Avoid the top most common mistakes made when buying, installing and using plastic pressure pipe. Information on pipe sizing, material & installation methods.

Solvent cement is used to chemically soften the surface of plastic pipes and fittings, so that when they are pushed together they become bonded. However, some plastics such as Polypropylene and Polyethylene are resistant to solvents and therefore need to be jointed with other methods. Check out this video on how polypropylene joints can be made

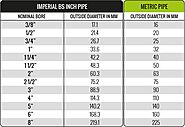

Metric & Imperial pressure pipe are separate systems and both are in common use in the UK. The fittings and pipe are not directly interchangeable between the two systems. Imperial designation doesn't refer to the outer diameter of the pipe. The chart above demonstrates that the closest equivalents between the two systems are actually incompatible without the use of special Metric-Imperial connectors. A great article for a more in-depth explanation

Pressure pipe and fittings are intended to convey media under pressure. Metric PVC pressure pipe is assigned a PN number, which is the pressure rating in bars. PN16, for example would have a maximum operating pressure of 16 bar. Whereas, imperial pressure pipe is divided into classes such as Class C and Class E which are rated as 9.0 bar and 15 bar respectively. Read more about pressure ratings and classes

Pipe clips are used to support pipework and the additional weight of the media being piped as it travels along walls or overhead. Using traditional pipe clamps designed for metal pipe on plastic pipe, will cause stress and damage in a number of ways. Always use pipe clips designed for plastic pipe, as these allow for thermal expansion in the pipe work. You can find clips specifically for use with plastic pipe here

All materials expand and contract with changes in temperature. Plastic is more susceptible to this natural phenomenon than other piping materials . Failing to account for the expected changes in temperature can have consequences on plastic pipework. How to avoid problems in plastic pipework from linear expansion

Each plastic material has its own profile of characteristics. Which is why there are different plastic pipe materials available. You will need to consider the piping application and choose the material suitable for your needs. The most common things you need to check are;

Temperature range

Chemical resistances

Impact & Abrasion Resistance

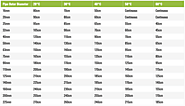

This is an easy error to make if you are unaware of how much cement you will need for making each joint. The amount of glue needed per joint depends on the pipe diameter. Of course, each product may differ in viscosity and therefore amounts needed. Based on the leading brand of cement here is a handy insight into how many joints can be made per pack size

Plastic pipe softens with increases in temperature and must be supported adequately with clips if running along walls or overhead. The above chart shows the correct support spacings for your PVC & ABS pressure pipe, pipe diameter and max temperature. Here is a full guide to recommended pipe support spacings