-

About

- About Listly

- Community & Support

- Howto

- Chrome Extension

- Bookmarklet

- WordPress Plugin

- Listly Premium

- Privacy

- Terms

- DMCA Copyright

- © 2010-2025 Boomy Labs

Nitpro Composites

Nitpro Composites

Listly by Nitpro Composites

Carbon fiber is a strong and lightweight material made from a long chain of carbon atoms that are tightly bonded together. It is used in a variety of applications, including aerospace, automotive, and sporting goods. This makes it much stronger than steel and much lighter than aluminum. Want to know how carbon is made? Follow our blog.

https://www.nitprocomposites.com/blog/how-carbon-fiber-is-made.php

Pultrusion is a continuous process for manufacturing composite materials with a constant cross-section. It can be used to produce a variety of composite shapes, including rods, Carbon Fiber Tubes, angles, channels, and I-beams.

https://www.nitprocomposites.com/blog/what-is-pultrusion.php

Weaves in carbon fiber are made from very thin strands of carbon that are interwoven in a particular pattern. The weave pattern affects the properties of the carbon fiber composite fabric, such as strength, stiffness, and density. The most common weave patterns are plain, twill, and satin. Know more about weave patterns in carbon fiber with our blog.

https://www.nitprocomposites.com/blog/what-are-weaves-in-carbon-fiber.php

The manufacturing process of carbon fiber rods begins with the spinning of a raw material, usually polyacrylonitrile (PAN), into a thread. These rods are used in a variety of industries, from aerospace to automotive as these rods can be cooled and cut to the desired length.

https://www.nitprocomposites.com/blog/how-carbon-fiber-rods-are-made.php

Carbon fiber and aluminum are two popular materials used in a variety of industries. With different properties and advantages for different applications, they both are useful. Understanding the pros and cons of both will help you determine which is right for the product you are designing and manufacturing. To know more, visit NitPro Composites.

https://www.nitprocomposites.com/blog/carbon-fiber-vs-aluminum-pros-cons

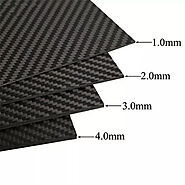

Unlock the Potential of Carbon Fiber Sheets! Impeccably crafted using advanced compression molding and vacuum infusion techniques, our carbon fiber composite sheets redefine excellence. Boasting unmatched rigidity, stability, and UV resistance, they are the ultimate choice for frames, trusses, and reinforcement. Experience the pinnacle of carbon fiber sheets with our premium collection today!

Visit: https://www.nitprocomposites.com/carbon-fiber-sheets

Do you know how carbon fiber is made? Prepare to be captivated by the fascinating process behind this cutting-edge material. From transforming polymers into resilient fibers to harnessing strength and lightness, discover the brilliance that empowers aerospace, automotive, and sporting industries.

Visit the link below to unveil the artistry behind our exceptional composites.

https://www.nitprocomposites.com/blog/how-carbon-fiber-is-made

Unlock the science behind vacuum bagging: the secret to crafting top-tier carbon fiber products. Whether it's for aerospace, automotive, or beyond, this method ensures peak performance. For premium carbon fiber solutions, turn to NitPro Composites.

https://www.nitprocomposites.com/blog/what-is-vacuum-bagging-process

Unravel the intricacies of compression molding and its transformative role in creating carbon fiber products. From aerospace to sports gear, understand the techniques driving durability and precision. Where engineering meets artistry!

https://medium.com/@nitprocomposites/what-are-3-types-of-compression-molding-ea3cf88cadef

Unlock the future of medical tech with carbon fiber! Revolutionizing device design, NitPro Composites leads in strength, flexibility, and imaging clarity. A game-changer for patient care and diagnostics.

https://www.nitprocomposites.com/blog/usage-of-carbon-fiber-sheets-in-medical-devices

Unleash the power of carbon fiber's unmatched strength and lightweight properties. Transform your projects with these versatile sheets, tubes, and rods. Also learn how to take good care of you carbon fiber.

https://www.nitprocomposites.com/blog/tips-and-tricks-for-keeping-your-carbon-fiber-in-good-shape

Delve into the captivating world of Carbon Fiber and Titanium, and uncover their exceptional qualities, head-to-head strength, and performance. Empower yourself with knowledge to make informed material choices.

https://www.nitprocomposites.com/blog/carbon-fiber-vs-titanium

NitPro Composites manufactures high-qaulity carbon fiber rods in various lengths and dimensions. It is widely used in various industries due to their exceptional strength-to-weight ratio, high tensile strength, stiffness, and resistance to corrosion. The composite rods are made by pultrusion process, where carbon fibers are impregnated with resin and then cured to form a solid structure as well as roll wrapping.

https://www.nitprocomposites.com/carbon-fiber-pultruded-rods

Nitpro International crafts high-strength, lightweight carbon fiber products. From tubes and sheets to fabrics and laminates, we offer solutions for various industries seeking superior performance.

Upgrade your structures with NITPro Composite's Carbon Fiber Fabric. Strengthen concrete, masonry, and timber elements with this versatile, cost-effective solution. High strength-to-weight ratio, durability, and easy installation – the key to structural excellence.

NitPro Composites manufactures high-quality carbon fiber rods in various lengths and dimensions. It is widely used in various industries due to their exceptional strength-to-weight ratio, high tensile strength, stiffness, and resistance to corrosion.

https://www.nitprocomposites.com/carbon-fiber-pultruded-rods