-

About

- About Listly

- Community & Support

- Howto

- Chrome Extension

- Bookmarklet

- WordPress Plugin

- Listly Premium

- Privacy

- Terms

- DMCA Copyright

- © 2010-2025 Boomy Labs

Nanotech Energy

Nanotech Energy

Listly by Nanotech Energy

Nanotech Energy Company is being recognized for its Energy Graphene Super Battery, which delivers a nonflammable, high-performing battery and is endorsed by Head of Electric at Daimler Mercedes.

A Few years ago, we challenged Nanotech Energy to provide us the safest battery chemistry, non-flammable, and extremely safe. We saw the challenge and created batteries that are safe, not just safer, last longer, charge faster and we manufacture in the United States.

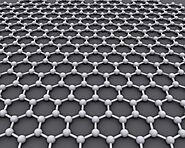

The graphene absorber is a thin, flexible, and light conductive layer manufactured using Nanotech SUPREME graphene technology. It has excellent electrical and thermal properties, as well as good mechanical flexibility and structural integrity.

Silver nanowires are one-dimensional nanomaterials having a number of exciting properties that are not exhibited by the bulk silver and spherical nanoparticles. These nanowires can be tuned to meet the requirements for most printing techniques including roll-to-roll, slot-die, gravure and flexographic printing.

Every single technical gadget is on a revolution mode and so does the batteries. With every new launch, we are seeing a new version of batteries, the most common battery i.e., lithium-ion battery.

The graphene absorber is a thin, flexible and lightweight conductive sheet produced based on Nanotech SUPREME graphene technology. It offers superior electrical and thermal properties along with excellent mechanical flexibility and structural integrity.

There are thousands of lithium Ion batteries that make up the battery pack. If they all catch on fire at the same time, the explosion is massive. They are so much concern about the lithium ion batteries igniting that the U.S. has banned transporting them in cargo and passenger flights.

The funding news dovetails with the Company’s creation and production of non-flammable, lithium batteries with highest performance levels of other batteries. The Nanotech Energy Graphene Super Battery safely delivers efficient, fast charging and long-lasting battery power.

The AAA Car Doctor John Paul chats with Dr. Jack Kavanaugh, founder and CEO of Nanotech Energy about the most recent developments in electric vehicle battery technology.

By reflecting and absorbing incident radiation, the is built to either keep out or keep in electromagnetic interference. It's also great for having heatsink in small spaces. We have absorber sheets in a variety of thicknesses to satisfy the needs of EMI shielding applications.

Graphene powder coating has a high density that helps in the improvement of its anti-oxidative and anti-corrosive characteristics, which ultimately extends its service life. Graphene coating is also resistant to corrosion of elements and substances like ultraviolet rays, rain, wind, etc. that is very helpful in prolonged protection.

Nanotechnology has the power to convert the simple manufacturing process into an advanced and hi-tech energy conversation process for efficient and better manufacturing. From thermal conductive glue to non-flammable batteries, the use of nanotechnology and its advanced products are creating a huge difference.

The funding news dovetails with the Company’s creation and production of non-flammable, lithium batteries with the highest performance levels of other batteries. The Nanotech Energy Graphene Super Battery safely delivers efficient, fast charging and long-lasting battery power.

Governments around the world are taking responsible steps towards the adoption of clean energy technologies while reducing dependence on oil. This calls for electric vehicle manufactures, electric utilities and states to work together towards putting more electric vehicles on the road.

Lithium-ion batteries have transformed the way society uses energy. They can hold a lot of charge in a small volume, allowing cell phones, laptop computers, and even electric cars to exist. So, they are closely related to our daily lives but they have obvious safety issues. A battery, if shorted, could become a fireball bomb nearly impossible to extinguish using conventional techniques.

As graphene is very lightweight and possesses excellent thermal, electrical, and conductive properties, so it becomes easier to use the graphene powdered EMI shielding absorber. The graphene absorber comes in various forms as several manufactures prove that it is not impossible to develop such an advanced product.

One of the most advanced and versatile products of nanotechnology which is graphene is used in many different applications. It is used in applications such as EMI shielding materials, conductive epoxy, and lithium-ion batteries. The graphene powdered batteries are very realizable to use in various applications.

Experience in the lithium ion battery industry is preferred. Knowledge and understanding of lithium ion battery industry including material selection, electrode manufacturing, cell assembly, testing and failure mode analysis are necessary.

Different products of nanotechnology are capable of providing efficient and safer solutions in many working operations especially in the industries. Products such as EMI shielding solutions and non-flammable batteries are relatively capable to show the great extent at the industrious level.

Graphene can improve the surface area and electronic conductivity of the lithium-ion battery anode and cathode. According to the company, these nanostructured electrodes “enable a new generation of lithium-ion batteries with excellent power density, exceptionally high energy density and long cycling life.

The company intends to use the funds to expand its production of graphene batteries, as well as the production of conductive epoxies, conductive inks and electromagnetic interference shielding spray paints and films.

The Company’s creation and production of non-flammable, lithium batteries with highest performance levels of other batteries. The Nanotech Energy Graphene Super Battery safely delivers efficient, fast charging and long-lasting battery power.

Electrolyte plays an important role in the battery as it provides medium for the movement of lithium ions between the anode and cathode. The electrolyte is made by dissolving a lithium salt in the proper solvent whereas additives are often used to improve the cycling stability of the battery. Only electrolytes that meet stringent requirements can be used in a lithium ion battery.

The use of graphene in the making of more affordable and efficient batteries can provide benefits and real-life changes. From the solar industry to use it in the making of electric vehicle batteries, the versatility and need of graphene can be easily understood.

This round of funding allows us to dramatically expand our production of graphene batteries, as well as our production of conductive epoxies, conductive inks and electromagnetic interference shielding spray paints and films.