-

About

- About Listly

- Community & Support

- Howto

- Chrome Extension

- Bookmarklet

- WordPress Plugin

- Listly Premium

- Privacy

- Terms

- DMCA Copyright

- © 2010-2025 Boomy Labs

cbrandauer

cbrandauer

Listly by cbrandauer

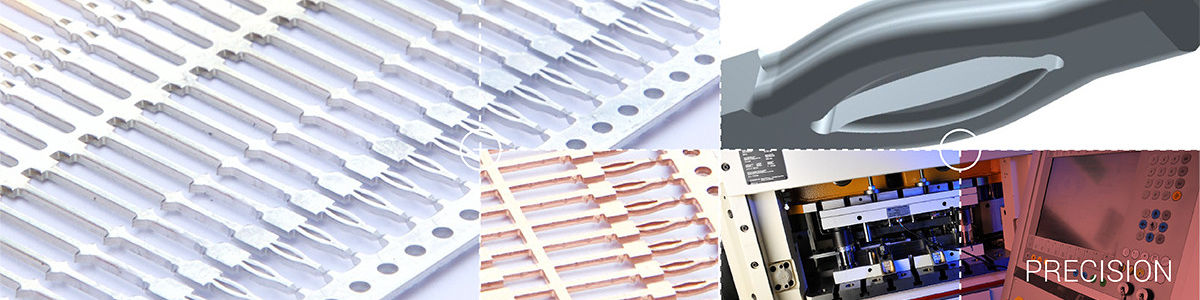

The EloPin Press-fit is an innovative product developed by leading German design office, TBS Sorig. EloPin press-fit pins allow for the solderless connection of wire wrap pins to a printed circuit board, allowing for a gas-tight and more reliable connection. Here, we have listed some of the most important things that you need to know about the product:

There are three standard pin sizes available: 06-10 0.60mm, 08-145 0.80mm, 08-16 0.8mm. Each pin size features a different press-in and push-out force and different resistance and current-carrying capacity.

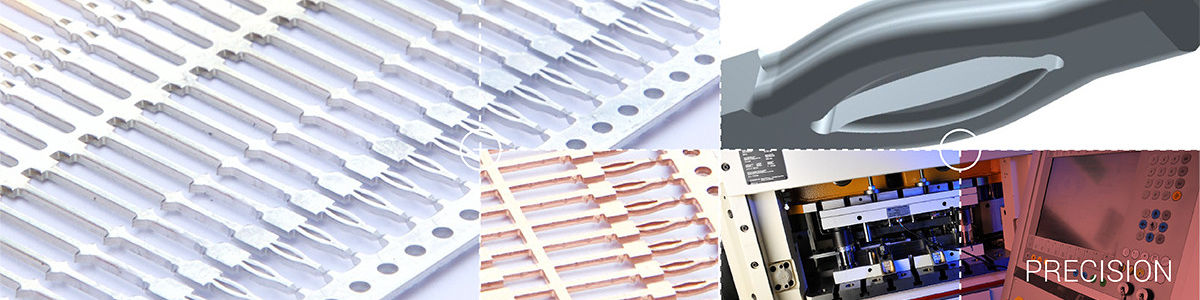

EloPin press-fit pins can be adapted to comply with customer’s bespoke requirements. Prototype press-fit terminals to suit specific requirements can be manufactured in just 15 days. Needle eye technology means that they are well suited to automated manufacture, providing excellent efficiency.

Press-fit components are aimed at customers involved in a number of sectors. For example, press-fit pins provide an ideal solution for automotive electronics. By allowing for solderless connection, circuit boards are able to better withstand the harsh environmental conditions experienced within a vehicle. With this in mind, press-fit pins are well suited for any manufacturers that are looking for improved efficiency and more robustness in electronic interconnects.

There are a number of factors that make EloPin an ideal solution for a number of industries:

To produce bespoke EloPin Press-Fit products, 3D CAD software can be used in conjunction with world class press-stamping machinery.

EloPin Press-Fit is now being manufactured in the UK by Brandauer. The Birmingham based company has partnered with TBS Sorig and are the only UK supplier of the EloPin range press-fit pins. Demand is expected to be huge, with Brandauer predicted to produce millions of components every year, including £1m of sales in the first year.

Whilst Brandauer have only recently formed a partnership with TBS Sorig, they have been manufacturing press-fit components for more than two decades, continually investing in their state-of-the-art premises near Birmingham city centre.