-

About

- About Listly

- Community & Support

- Howto

- Chrome Extension

- Bookmarklet

- WordPress Plugin

- Listly Premium

- Privacy

- Terms

- DMCA Copyright

- © 2010-2025 Boomy Labs

i- SCOOP

i- SCOOP

Listly by i- SCOOP

Defining the fourth industrial revolution, known as Industry 4.0.

Source: https://www.i-scoop.eu/industry-4-0/

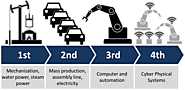

Industry 4.0 refers to the fourth industrial revolution. After mechanisation (Industry 1.0), mass production (Industry 2.0) and automation (Industry 3.0), now the “internet of things and services” is becoming an integral part of manufacturing. Industry 4.0 technologies have the potential to create extraordinary growth opportunities and competitive advantages for Germany as a business location. Experts forecast that businesses will be able to increase their productivity by about 30 percent using Industry 4.0.

Smart industry or “INDUSTRIE 4.0” refers to the technological evolution from embedded systems to cyber-physical systems. Put simply, INDUSTRIE 4.0 represents the coming fourth industrial revolution on the way to an Internet of Things, Data and Services. Decentralized intelligence helps create intelligent object networking and independent process management, with the interaction of the real and virtual worlds representing a crucial new aspect of the manufacturing and production process. INDUSTRIE 4.0 represents a paradigm shift from “centralized” to “decentralized” production – made possible by technological advances which constitute a reversal of conventional production process logic. Simply put, this means that industrial production machinery no

longer simply “processes” the product, but that the product communicates with the machinery to tell it exactly what to do. INDUSTRIE 4.0 connects embedded system production technologies and smart production processes to pave the way to a new technological age which will radically transform industry and production value chains and business models (e.g. “smart factory”).

Industry 4.0 is the next phase in the digitization of the manufacturing sector, driven by four disruptions: the astonishing rise in data volumes, computational power, and connectivity, especially new low-power wide-area networks; the emergence of analytics and business-intelligence capabilities; new forms of human-machine interaction such as touch interfaces and augmented-reality systems; and improvements in transferring digital instructions to the physical world, such as advanced robotics and 3-D printing.

Industry 4.0 is a collective term for technologies and concepts of value chain organization. Based on the technological concepts of cyber-physical systems, the Internet of Things and the Internet of Services, it facilitates the vision of the Smart Factory. Within the modular structured Smart Factories of Industry 4.0, cyber-physical systems monitor physical processes, create a virtual copy of the physical world and make decentralized decisions. Over the Internet of Things, Cyber-physical systems communicate and cooperate with each other and humans in real time. Via the Internet of Services, both internal and cross-organizational services are offered and utilized by participants of the value chain.

In this PDF document from the European Parliament, Industry 4.0 is defined as follows: "Industry 4.0 is a term applied to a group of rapid transformations in the design, manufacture, operation and service of manufacturing systems and products. The 4.0 designation signifies that this is the world's fourth industrial revolution, the successor to three earlier industrial revolutions that caused quantum leaps in productivity and changed the lives of people throughout the world.

Industry 4.0 is the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of things and cloud computing. Industry 4.0 creates what has been called a "smart factory".

Industrie 4.0 is a German-government-sponsored vision for advanced manufacturing. The underlying concept of Industrie 4.0 is to connect embedded systems and smart production facilities to generate a digital convergence between industry, business and internal functions and processes. Industrie 4.0 refers to a fourth industrial revolution (following water/steam power, mass production and automation through IT and robotics) and introduces the concept of "cyber-physical systems" to differentiate this new evolutionary phase from the electronic automation that has gone before.

Industry 4.0 is the digital transformation of manufacturing/production and related industries and value creation processes. Industry 4.0 is used interchangeably with the fourth industrial revolution and represents a new stage in the organization and control of the industrial value chain.and a fundamental transformation in industrial production.

Industry 4.0 was originally the name of a German Federal Government project to promote digitization in manufacturing. It has since become accepted as a general term for networked, digitized production: machines and products are seen as networked and intelligent components that can exchange data locally, globally and among companies. The idea is to achieve unprecedented transparency and flexibility (Daniel Stock, expert at the Fraunhofer Institute for Manufacturing Engineering and Automation).